TABLE OF CONTENTS

- The Appeal of Holographic Stickers

- What Are Holographic Stickers?

- Choosing the Right Holographic Material

- Design Tips for Maximum Shine

- Printing Methods: DIY vs. Professional

- Best Printers & Inks for Holographic Stickers

- Laminating & Finishing Touches

- Cutting & Shaping Your Stickers

- Common Mistakes to Avoid

- Conclusion

- Frequently Asked Questions

- Home

- content hub

- How To Print Holographic stickers

How To Print Holographic stickers

Matthew Prince

Content Writer

Nov 25, 20226329 views

Nov 25, 20226329 views

TABLE OF CONTENTS

- The Appeal of Holographic Stickers

- What Are Holographic Stickers?

- Choosing the Right Holographic Material

- Design Tips for Maximum Shine

- Printing Methods: DIY vs. Professional

- Best Printers & Inks for Holographic Stickers

- Laminating & Finishing Touches

- Cutting & Shaping Your Stickers

- Common Mistakes to Avoid

- Conclusion

- Frequently Asked Questions

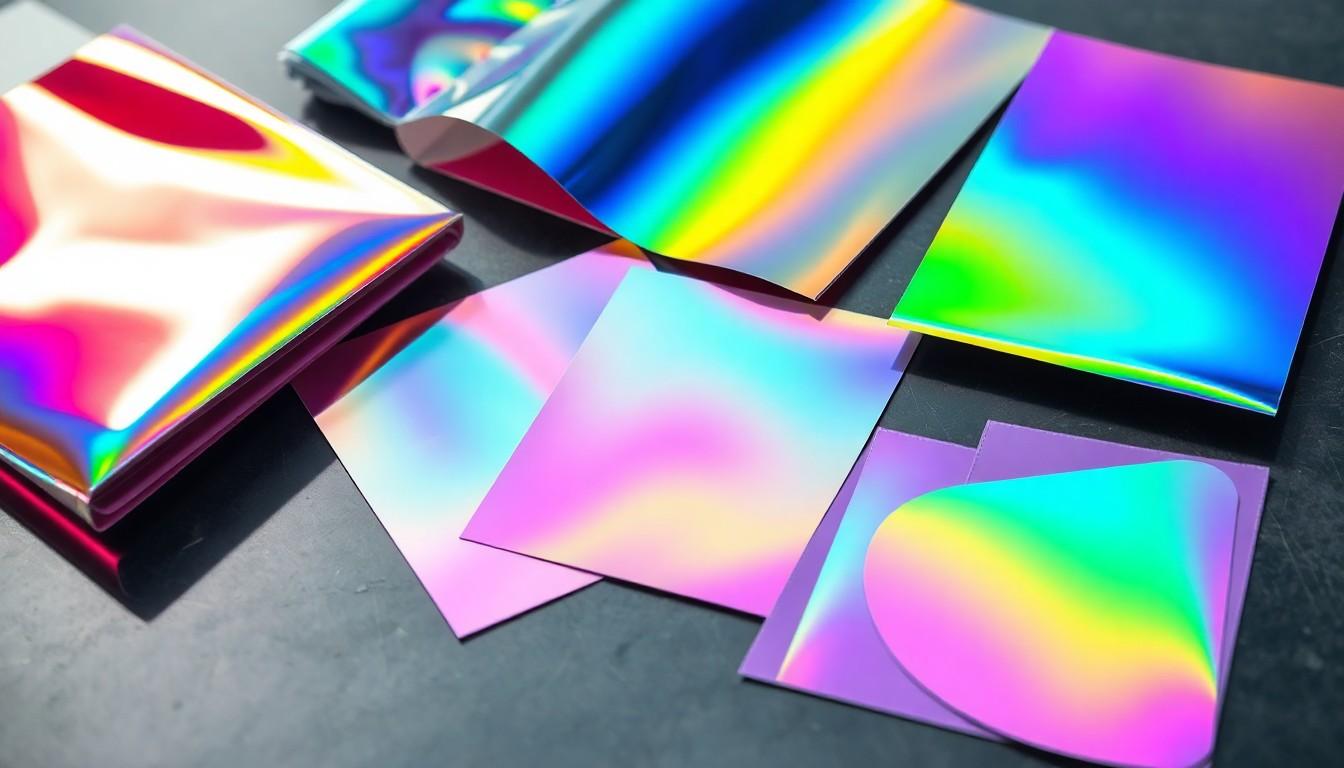

Holographic stickers have taken the world by storm with their dazzling rainbow-like shine and futuristic appeal. Whether you're looking to add a unique touch to your personal items or elevate your brand's packaging, these eye-catching stickers are a perfect choice. But creating them yourself might seem like a daunting task—don’t worry, we’ve got you covered.

In this article, we’ll guide you through the process of printing your own holographic stickers with ease. From choosing the right materials to achieving that mesmerizing holographic effect, we’ll break it all down step by step. Get ready to transform your designs into stunning stickers that stand out and leave a lasting impression.

The Appeal of Holographic Stickers

Holographic stickers captivate audiences with their dynamic rainbow-like reflections. The iridescent glow makes these stickers stand out on any surface, drawing attention to product packaging, promotional materials, or branding efforts. By adding a holographic sticker, businesses can create a lasting impression that highlights quality and uniqueness.

These stickers also offer significant functional advantages. Their durable laminations make them waterproof and tearproof, ensuring longevity indoors or outdoors. The premium metallic sheen not only enhances aesthetics but also serves as a tamperproof security measure. This added level of trust reassures customers, especially in industries like beauty, pharmaceuticals, and healthcare.

At 4OVER4.COM, we specialize in printing custom holographic stickers to meet the unique needs of businesses looking to elevate their brand presence. Whether it’s intricate logos or striking designs with full-color prints, our stickers combine aesthetic appeal with practicality.

Why Businesses Love Holographic Stickers

- Eye-Catching Design

The holographic effect transforms standard designs into dazzling visuals. Products boasting reflective labels consistently stand out, giving brands an edge on crowded shelves. Customers naturally gravitate toward packaging with premium finishes.

- Premium Association

Holographic stickers evoke prestige. Consumers perceive brands that use them as more sophisticated, aligning with high-quality or luxury items. This perception adds intrinsic value to products.

- Versatility

These stickers adhere seamlessly to various materials, including glass, plastic, or cardboard. Practical for different industries, they can enhance product labels, promotional giveaways, or event branding.

- Anti-Counterfeit Feature

High-quality holographic stickers, like those available via our sticker printing services, are challenging to replicate. This characteristic proves crucial for protecting brand integrity against counterfeits.

Explore Holographic Possibilities with Advanced Printing

When paired with custom designs, holographic stickers unlock creative opportunities. A sleek company logo printed on this material effortlessly grabs attention. Coupled with UV lamination, stickers become highly durable and resistant to water or weather damage. This makes them ideal for outdoor applications.

At 4OVER4.COM, we craft our stickers with high-quality holographic vinyl and premium adhesives, ensuring strong adhesion across surfaces. Whether presented individually or on rolls, each sticker embodies careful craftsmanship. Discover more about how holographic stickers are made and why they’re a game changer for businesses. By selecting holographic stickers, businesses balance visual appeal with functionality, building trust and visibility in equal measure.

What Are Holographic Stickers?

Holographic stickers are visually striking stickers crafted from iridescent vinyl, known for their distinctive rainbow-like effect. These stickers enhance any design by reflecting light, creating dynamic color shifts as they move. Ideal for packaging, branding, or personal use, they are both functional and visually appealing.

Material and Effect

Holographic stickers are made using iridescent vinyl, which is durable and features a reflective, prismatic quality. The iridescent effect results from a thin metal layer applied to a polyester film, embossed to refract light. This process generates the shimmering, multi-color appearance customers find captivating. The material's thickness also ensures strong adhesion to various surfaces.

Manufacturing Process

To create holographic stickers, the design is printed onto the vinyl material. A clear laminate is added over the design to protect it from water, wear, and sunlight. The stickers are then cut into desired shapes, providing flexibility for custom designs. Unlike standard stickers, this process uses specialized materials that create a blend of durability and aesthetic charm.

More details on the holographic sticker-making process explain why their vibrant finish resists environmental damage, making them popular for indoor and outdoor applications.

Practical Use and Appeal

Holographic stickers don't just stand out visually—they're also highly functional. Many industries, including beauty and pharmaceuticals, use these stickers for tamperproofing, anti-counterfeit measures, and improved shelf appeal. These applications elevate the perceived value of products, making them synonymous with quality and security.

Custom holographic printing, such as ours at 4OVER4.COM, enables businesses to create captivating designs tailored to specific needs. Options like glossy or matte finishes allow brands to achieve the desired effect while maintaining functionality.

Features Setting Holographic Stickers Apart

- Uniqueness: Reflective designs provide a futuristic, premium look.

- Durability: Water-resistant, tamperproof, and weatherproof properties ensure longevity.

- Adaptability: Compatible with various shapes, surfaces, and laminates for enhanced design flexibility.

- Versatility: Used for labels, product packaging, and promotional items.

For businesses seeking to enhance branding, custom stickers like these deliver unmatched design advantages.

Choosing the Right Holographic Material

Holographic Vinyl or Sticker Paper

We craft holographic stickers by printing designs on iridescent vinyl or holographic sticker paper. This specialized material is composed of metalized polyester film, embossed to create a light-diffracting surface. This production method results in vibrant rainbow-like reflections, ideal for branding and product packaging.

Types of Finishes

Customizable finishes allow us to match holographic designs to specific branding needs. Glossy finishes amplify the vibrant, reflective effects, while matte finishes provide a subtle, non-reflective appearance. Transparent finishes reveal the underlying surface, adding depth and allowing creative layering effects. These finish options offer businesses flexibility in creating unique, professional designs. Explore different sticker customization options to refine your choice.

Holographic Foil

We also implement holographic foil in techniques like hot stamping to transfer holographic effects onto surface materials. This method adds premium texture and sheen, making designs more dynamic and professional. Integrating foil can enhance not only the aesthetic appeal but also the perceived value of your stickers.

Design Tips for Maximum Shine

Use Negative Space

Leaving parts of a design transparent enhances the holographic material's visual impact. The uncovered sections let the iridescent vinyl shine through, adding a polished and dynamic effect to the sticker. Negative space works well with minimalist designs and intricate patterns, highlighting the sticker’s reflective quality. Utilizing transparency to frame key design elements creates a clean and eye-catching presentation.

Adjust Color Saturation

Lighter colors complement holographic surfaces by blending effortlessly with the material’s prismatic reflections. Darker shades, like deep navy or black, tend to overshadow the holographic effect, making it less prominent. Opting for pastel shades or soft gradients ensures the design harmonizes with the rainbow-like shine. For intricate designs, balancing lighter and darker hues creates depth without reducing the holographic appeal.

Leverage Custom Printing

Our custom printing services at 4OVER4.COM help businesses incorporate advanced techniques to maximize visual appeal. Features like holographic sticker paper and professional-grade laminates boost durability and vibrancy. Business owners can explore unique finishes and tailor designs, enhancing their branding with premium, custom holographic stickers. Check out the options we offer for custom holographic stickers to create truly memorable prints.

Optimize Detail Visibility

Detailed artwork requires clarity to complement holographic materials effectively. High-resolution designs and scalable vector files ensure precision during printing, leaving no room for blurring or distortion. Simplifying complex elements while maintaining essential features enhances visibility and ensures consistency in the final product.

Add Protective Laminates

Protective laminates safeguard stickers by adding a glossy layer that boosts shine and prevents UV or water damage. This extra durability makes holographic stickers suitable for outdoor and long-term use. 4OVER4.COM uses high-quality lamination to maintain sticker integrity while elevating the overall aesthetic.

For businesses aiming to expand their branding reach, holographic stickers offer a stylish, functional solution. Using customization tools like the ones available on our stickers page helps create designs that stand out. Leveraging these tips amplifies the unique features of holographic materials, ensuring stickers leave a lasting impression.

Printing Methods: DIY vs. Professional

Holographic stickers can be printed using DIY methods or professional services like those offered by 4OVER4.COM. Both approaches have unique benefits, depending on the desired quality, volume, and application.

DIY Printing

DIY printing is suitable for small-scale projects, personal use, or limited budgets. By using holographic sticker paper or printable holographic vinyl and a compatible inkjet or laser printer, we can create stickers from home. Inkjet printers work best for vibrant colors, while laser printers deliver sharper details. Design software like Adobe Illustrator or Canva allows us to customize graphics, experiment with bold shapes, and use transparent areas to emphasize the holographic shine.

However, DIY methods may lack the durability and precision of professionally printed stickers. Protective laminates and cutting accuracy might also be a challenge without advanced equipment. If large volumes or uniform quality are a priority, DIY may not suffice.

Professional Custom Printing

Professional printing through 4OVER4.COM ensures high-quality, durable holographic stickers with advanced finishes. Using top-grade iridescent vinyl and precise cutting machinery, professional services deliver consistent results. These stickers are waterproof, tearproof, and ideal for outdoor or high-demand applications. Custom holographic stickers produced professionally elevate branding efforts and offer a polished, premium appearance with anti-counterfeit benefits.

Businesses working with 4OVER4.COM can access tailored solutions for distinct branding needs, including unique shapes, finishes, and protective laminates. The platform’s customization tools simplify the process while maintaining exceptional detail visibility and resistance to wear. This is invaluable for brands looking to enhance packaging or promotional materials.

For those aiming to achieve standout results, professional printing services ensure unmatched quality that DIY attempts might not deliver. Custom options at 4OVER4.COM help create stickers that captivate attention, making them a versatile and impactful addition to any branding strategy.

Best Printers & Inks for Holographic Stickers

Choosing the right printers and inks ensures vibrant, high-quality holographic stickers that leave a lasting impression. At 4OVER4.COM, our custom printing solutions are designed to help businesses elevate their brand presence by delivering professional-grade results.

Inkjet Printers for Precision

Inkjet printers are optimal for producing holographic stickers due to their precision and compatibility with specialty materials. These printers support full-color printing with high-resolution output, enhancing the vividness and clarity of designs. Their capability to work on holographic vinyl or metalized polyester films makes them a preferred choice for crafting dazzling and durable stickers.

Ideal Inks for Superior Quality

Using pigment-based inks ensures that printed designs remain sharp, resistant to fading, and adhere seamlessly to protective laminates. Combined with holographic materials, these inks enhance contrast and shine for a polished, professional finish. Our custom holographic stickers are a perfect example of how high-quality inks can amplify design impact.

Key Equipment Features

Compatible printers must support various printing formats and offer accurate ink application. This ensures the holographic sheen complements the printed graphics. By combining durable substrates with advanced printing capabilities, we guarantee that the final product not only looks stunning but also meets practical requirements like water and tear resistance, crucial for applications such as branding and promotional materials.

Enhancing Results with 4OVER4.COM

We utilize the latest technology to handle any custom request for holographic stickers. Our expertise allows clients to explore options like glossy or matte UV laminates, ideal for protecting stickers and enhancing their reflective features. Visit our stickers category to view the wide range of solutions available for transforming designs into visually captivating stickers.

Laminating & Finishing Touches

To enhance the durability and appearance of holographic stickers, adding a laminate is essential. The laminating process protects the stickers from water, scratches, and fading while intensifying their shine for a premium finish. We begin by heating up the laminator, ensuring it's set to the hot setting for the best results.

Using a folded piece of printer paper as a carrier, we arrange the printed stickers on the bottom half. After measuring the laminate to cover all stickers, we cut it to size and place it over the arranged stickers. Folding over the top half of the printer paper secures everything, preventing shifting during lamination.

We insert the folded end of the paper carrier into the laminator, running it through twice to ensure full adherence. This step creates a smooth, professional finish. Finally, peeling off the sticker backing reveals a glossy and durable surface, ideal for both indoor and outdoor use.

For businesses seeking consistent premium quality for their branding needs, 4OVER4.COM offers custom holographic stickers tailored to elevate products and promotional materials. From incorporating protective laminates to precision cutting, we ensure every detail is perfected. Explore more in our sticker printing category to enhance your projects.

Cutting & Shaping Your Stickers

Accurate cutting ensures holographic stickers match your design and specifications. Using tools like a Cricut machine provides the precision needed to achieve polished results. First, attach your printed holographic material to a Cricut mat. Accurate placement prevents misalignment during cutting. Place the mat into the machine, export your design using compatible software, and select the appropriate material type. Finally, activate the cutter to create your custom shapes.

Lamination Before Cutting

Applying laminate before cutting enhances durability and appearance. Two methods can be used for this step: the Foil-On laminating method or the self-adhesive laminate method. For the Foil-On method, run your stickers through a heated laminator using folded printer paper as a carrier. If using self-adhesive laminate, carefully align and apply the laminate directly to your sticker sheet. This preparation step safeguards the holographic material while reinforcing its vibrant, prismatic quality.

Internal Cuts for Custom Shapes

Internal cuts add intricate details to your stickers, perfect for logos or complex branding designs. While we can provide internal cuts, these areas remain in place until manually removed. This option creates additional customization opportunities, helping businesses achieve unique designs with 4OVER4.COM’s advanced printing solutions.

Explore Versatile Customization Options

We use innovative cutting techniques, enabling consistency and creativity for various sticker needs. Explore custom holographic stickers to access tailored shapes that go beyond simple outlines. These cutting capabilities enhance branding by offering options like kiss-cut stickers or complete die-cut designs.

Benefits of Precision Cutting

When stickers are professionally cut, the result is smooth, clean edges that elevate product presentation. The high precision we achieve helps maintain sticker alignment, ensuring your designs integrate seamlessly with their holographic backgrounds. Check out our available sticker options to learn how cutting methods can impact your branding projects.

Guide for DIY Applications

Those opting for at-home preparation can still achieve quality outcomes with an inkjet printer, holographic sticker paper, and a cutting machine. Combine these materials with step-by-step design guidance for an efficient setup. For more on holographic sticker creation, read our in-depth guide, which includes practical tips for design, printing, and cutting.

Common Mistakes to Avoid

Ignoring Material Compatibility

Using incompatible materials leads to subpar printing results. Opt for quality holographic sticker paper or vinyl to ensure durability and vivid colors. At 4OVER4.COM, we prioritize premium materials to produce high-quality, custom holographic stickers tailored to your needs. For reference, explore the different sticker types available to elevate your branding.

Overlooking Negative Space

Filling every inch of a design can overshadow the holographic effect. Incorporating negative space enhances the iridescent sheen and adds depth to your stickers. This technique is essential for maximizing the visual impact.

Choosing the Wrong Colors

Dark and saturated hues diminish the holographic effect by reducing reflectivity. Lightweight pastel colors complement the reflective material without overwhelming it. Adjusting color saturation helps in balancing holographic shine with design clarity.

Using Low-Resolution Designs

Printing designs with low resolution results in pixelation and loss of detail. Graphics need to be high-resolution (at least 300 dpi) to achieve a professional finish. 4OVER4.COM ensures every custom sticker maintains sharpness by utilizing advanced printing techniques. See how holographic stickers are made for more insights.

Skipping Protective Lamination

Without lamination, holographic stickers may fade or scratch over time. Laminating enhances longevity, shine, and resistance to water or wear. Protective laminate sheets, combined with precision cutting, result in polished designs. Our team at 4OVER4.COM incorporates laminates for premium-quality stickers that endure.

Inconsistent Cutting Accuracy

Crooked edges or inconsistent shapes compromise the final product's quality. A Cricut or similar cutting tool ensures precision, preserving intricate details. At 4OVER4.COM, we provide precise die-cut options, allowing unique shapes that complement your brand identity. Browse our custom holographic sticker page for inspiration.

Conclusion

Holographic stickers are more than just visually stunning—they're a powerful tool for branding and creativity. Whether you're crafting them at home or opting for professional services like 4OVER4.COM, the right materials, techniques, and design choices can make all the difference. By focusing on precision, durability, and creativity, we can create stickers that captivate and leave a lasting impression. Let's embrace the versatility of holographic stickers to elevate our projects and showcase our unique style.

Frequently Asked Questions

What are holographic stickers made of?

Holographic stickers are made from iridescent vinyl or holographic sticker paper, which is often crafted from metalized polyester film. This material creates light-diffracting, prismatic effects that provide the stickers with a vibrant, reflective sheen.

How do I make holographic stickers at home?

To create holographic stickers at home, you’ll need holographic sticker paper, a compatible printer (preferably inkjet), and pigment-based inks for long-lasting designs. Print your design, apply a clear laminate for protection, and then cut the stickers into your desired shapes using scissors or tools like a Cricut machine.

Why are holographic stickers so popular for branding?

Holographic stickers are popular due to their eye-catching shine, which adds a premium and modern feel to branding. They’re durable, waterproof, and tamperproof, making them ideal for industries like beauty, healthcare, and product packaging.

Can holographic stickers be waterproof?

Yes, holographic stickers are waterproof, especially when laminated. The clear protective laminate shields them from moisture, scratches, and fading, ensuring they maintain their quality for both indoor and outdoor use.

What equipment is best for making holographic stickers professionally?

Professional services use advanced printers with high-resolution output, precise cutting machines, and laminating equipment to ensure consistent results. Inkjet printers with pigment-based inks and materials like iridescent vinyl are also key for high-quality production.

What mistakes should I avoid when making holographic stickers?

Common mistakes include using low-resolution designs, skipping protective laminations, incorrect material choices, poor color combinations, and inaccurate cuts. Ensuring compatible materials and using high-resolution designs can help prevent these errors.

Can I use negative space in holographic sticker designs?

Yes, leveraging negative space can enhance the reflective holographic effect. Leaving portions of the sticker unprinted lets the holographic material shine through, creating a more visually striking design.

How do I laminate holographic stickers?

To laminate holographic stickers, place a clear laminate sheet over your printed stickers. Use a laminator for a smooth, professional finish. Ensure the stickers are arranged flat and avoid air bubbles for the best results.

Are holographic stickers customizable for specific branding needs?

Absolutely! Holographic stickers can be customized with various finishes (glossy, matte, or transparent), unique shapes, and tailored designs to match branding goals. Businesses can also integrate anti-counterfeit and tamperproof features for added functionality.

What’s the difference between DIY and professional holographic sticker production?

DIY production is affordable and ideal for small projects, but it may lack durability and precision. Professional services provide high-quality, durable stickers with advanced finishes, unique shapes, and protective laminates, making them perfect for consistent business branding.

More from

4023

Business cards are still important for marketing in 2024. For e

Emma Davis

Oct 10, 2024

6538

Celebrating a loved one's birthday is a special occasion, and finding the perfect words to express your feelings can make their day even m

Emma Davis

Oct 4, 2024

10315

Whether you're an established business magnate or an emerging entrepreneur on the rise, one thing remains undeniable:

Emma Davis

Feb 19, 2024

18909

People often overlook the importance of pocket folders in businesses. This is the world of digital media where LinkedIn and Google g

Feb 17, 2024

9909

A well-designed business card is important for making a memorable first impression. It represents your brand

Emma Davis

Jan 10, 2024

9477

In the world of networking, a business card serves as more than just a piece of paper; it’s a vital tool for making lasting connections.

Matthew Prince

Dec 28, 2023

7791

New digital features have been introduced to business cards, making business connections more effective than they used to be. Technology has r

Matthew Prince

Dec 20, 2023

17074

First impression matters, especially when marketing your small business. An effective business card design will help you impress potential pro

Matthew Prince

Dec 14, 2023