TABLE OF CONTENTS

- What is a Standoff Screw?

- Standoff Screws vs. Traditional Mounting

- Common Materials Used for Standoff Screws

- How Standoff Signage Works

- Types of Standoff Screws for Signage

- Step-by-Step Installation Guide

- Best Surfaces for Standoff Signage

- Benefits of Using Standoff Mounting

- Design Tips for Standoff Signage

- Conclusion

- Frequently Asked Questions

- Home

- content hub

- What is a Standoff Screw? How Standoff Signage Works

What is a Standoff Screw? How Standoff Signage Works

Get acrylic prints NowEmma Davis

Content Writer

Aug 29, 20196376 views

Aug 29, 20196376 views

TABLE OF CONTENTS

- What is a Standoff Screw?

- Standoff Screws vs. Traditional Mounting

- Common Materials Used for Standoff Screws

- How Standoff Signage Works

- Types of Standoff Screws for Signage

- Step-by-Step Installation Guide

- Best Surfaces for Standoff Signage

- Benefits of Using Standoff Mounting

- Design Tips for Standoff Signage

- Conclusion

- Frequently Asked Questions

When working on electronic projects or installations, we often encounter the need for reliable spacing solutions. That's where standoff screws come into play. These versatile fasteners create essential gaps between components, ensuring proper airflow, preventing electrical shorts, and maintaining the integrity of our designs.

Understanding standoff screws is crucial for anyone involved in electronics, from hobbyists to professionals. They come in various shapes and materials, each serving a specific purpose. In this article, we’ll explore what standoff screws are, their different types, and how they can enhance our projects. By the end, we’ll have a clearer picture of how to effectively incorporate these handy components into our work.

What is a Standoff Screw?

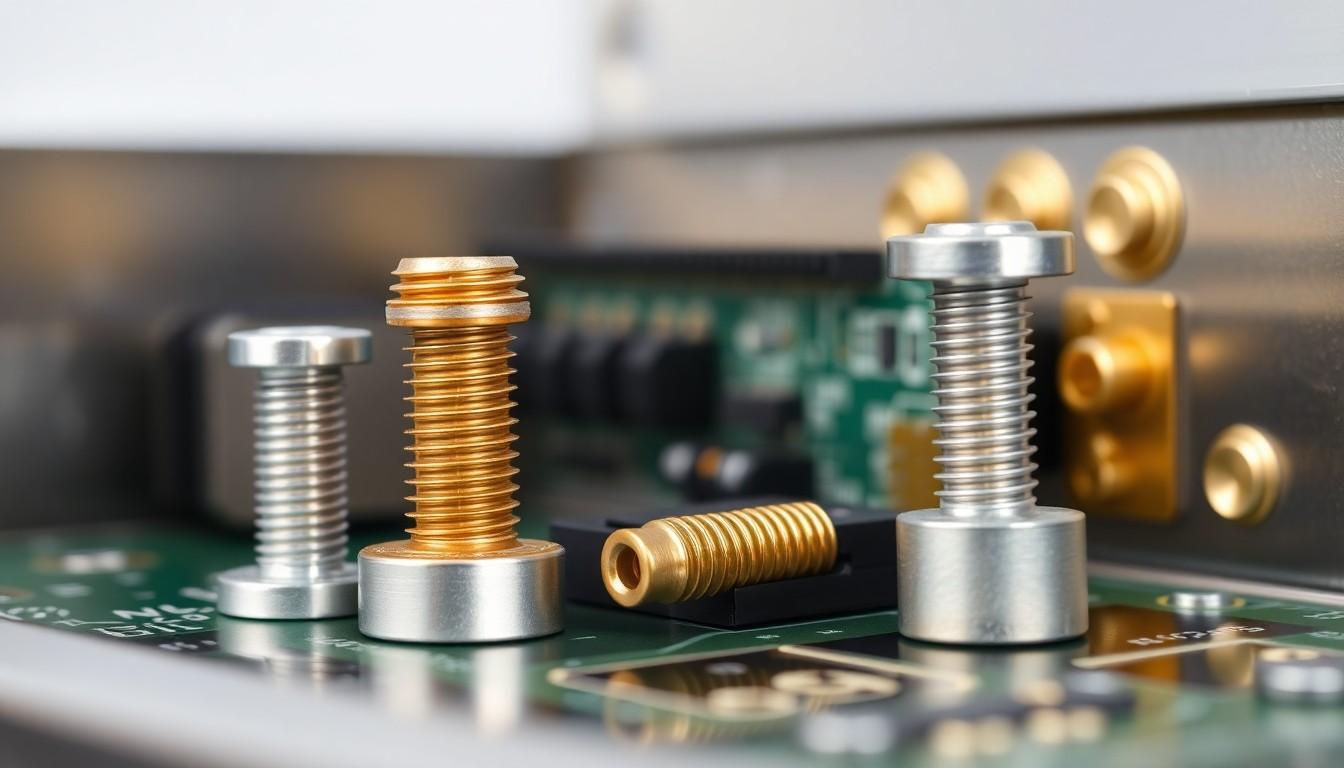

A standoff screw serves as a unique fastener designed to create distance between surfaces. Standoffs typically resemble a threaded screw and consist of three main components: a wall, a screw barrel, and a cap. These components allow for secure mounting, ensuring that items are positioned at the desired height and spacing.

Standoff screws come in various materials, including nylon, brass, and aluminum. Each material offers distinct advantages: brass is favored for its good thermal conductivity and resistance to rust, while aluminum provides a lightweight option without sacrificing strength.

Standoff screws are commonly used in the electronics sector to secure printed circuit boards (PCBs). Their ability to prevent electrical shorts by maintaining space between the PCB and the chassis is vital in protecting sensitive components. Additionally, standoff screws enhance airflow around the PCB, aiding in heat dissipation.

The versatility of standoff screws extends beyond electronics. In signage, they allow businesses to mount signs elegantly on walls, creating a three-dimensional effect. This adds depth to the display, elevating the visual appeal of our brand presence.

For those interested in expanding their signage options, exploring rigid signs can provide innovative solutions tailored to specific branding needs.

When employing standoff screws, consider the following styles: cylindrical, square, and hexagonal. Each shape offers specific aesthetic and functional benefits, allowing for design flexibility. The gendered forms, such as male, female, male-male, and male-female, enable compatibility across various applications.

Incorporating standoff screws in project designs not only improves functionality but also contributes to an overall polished look. Whether in electronics or display setups, standoff screws play a crucial role. Through strategic use of materials and styles, we can effectively enhance our projects while ensuring structural integrity and aesthetic appeal.

To further enrich our signage options, we can explore acrylic prints and reflective aluminum signs, which complement the visual impact of standoff-mounted displays.

Standoff screws are practical and visually appealing fasteners that enhance performance and design in a wide range of applications. They facilitate effective assembly while contributing to the overall aesthetics of our work.

Standoff Screws vs. Traditional Mounting

Standoff screws offer distinct advantages over traditional mounting methods. Traditional mounts typically rely on flat brackets or direct screws that can lead to limited airflow and potentially damage sensitive components. Standoff screws, on the other hand, maintain a specific distance between parts, boosting airflow, which is crucial for cooling electronic devices like printed circuit boards (PCBs).

Standoff screws also prevent potential electrical shorts. When using traditional mounting solutions, components may come into contact with surfaces that could create shorts. Standoff screws secure components while ensuring safe spacing, minimizing risks. Applications such as mounting PCBs to metal enclosures rely on standoff screws for reliable connections that protect from electrical hazards.

In the realm of signage, standoff screws elevate brand presence. They provide not only functionality but also aesthetic appeal. The three-dimensional effect achieved with standoff-mount systems enhances the visual impact of signs. Each component of the standoff system, such as the screws and washers, contributes to a professional look. For custom signage solutions, businesses can explore options like rigid signs or acrylic prints to enrich their branding efforts. We recognize the importance of clear and visually stunning displays, and how standoffs can augment this.

When it comes to materials, standoffs come in various options, including brass and aluminum. These materials provide durability and a polished finish, enhancing both electronic installations and physical displays. Traditional mounting often lacks such variety, limiting design versatility.

Choosing standoff screws proves beneficial in numerous applications. They secure components while improving airflow and offering visual enhancements in signage. Our commitment to providing exceptional printing solutions can help businesses enhance their brand identity. Explore our rigid signs and reflective aluminum signs for effective visibility and durability in your projects. For those interested in innovative display options, custom acrylic prints provide a modern take on branding.

Utilizing standoff screws not only strengthens structural integrity; it adds a layer of sophistication and professionalism to any assembly or display.

Common Materials Used for Standoff Screws

Standoff screws come in various materials, each providing unique properties suited for different applications. Here’s a breakdown of commonly used materials:

- Brass: Brass standoffs feature excellent thermal conductivity and corrosion resistance. Their non-magnetic nature makes them ideal for electronic applications, ensuring reliable performance without interference. Brass is also relatively soft, allowing for easy machining.

- Aluminum: Aluminum standoffs boast lightweight characteristics, providing strength without adding significant weight. Their resistance to oxidation and ability to dissipate heat make them popular in electronic assemblies. Aluminum is often chosen for its aesthetic appeal, offering a polished finish.

- Nylon: Nylon standoffs hold advantageous properties as well. They resist moisture, chemicals, and high temperatures, making them suitable for various environments. Their lightweight nature contributes to overall weight reduction in assemblies, while their non-conductive characteristics enhance safety in sensitive applications.

- Stainless Steel: Stainless steel standoffs provide high strength and superior corrosion resistance. They're ideal for harsh conditions where durability is critical. Their robust structure makes them suitable for heavy-duty applications in industries such as automotive and aerospace.

Applications of Standoff Screws

Standoff screws find utility in several applications, including:

- Printed Circuit Board (PCB) Mounting: Standoffs secure PCBs by positioning them away from metal surfaces. This prevents short circuits and allows for airflow, promoting thermal management.

- Signage Display: In signage, standoffs create a three-dimensional effect that enhances brand visibility. They serve to mount rigid signs effectively, adding sophistication to displays. Explore options for rigid signs

and reflective aluminum signs to uplift branding efforts.

- Industrial Equipment Assembly: In machinery and equipment, standoff screws manage component spacing for improved functionality and maintenance access.

Visual Appeal of Standoff-Promoted Displays

When using standoff screws in signage, achieving a clean, modern look is effortless. These screws elevate design aesthetics, creating striking displays that attract attention. For additional creative solutions, consider acrylic prints which can complement your standoffs effectively.

Through the use of various materials, standoff screws serve crucial roles in electronic installations and visual displays. They contribute to structural integrity and enhanced visual appeal, demonstrating their importance across multiple sectors. For more detailed instances of effective use of materials in signage, check out our guide on rigid sign printing.

How Standoff Signage Works

Standoff signage enhances visual appeal through a unique mounting technique. The process involves using standoff screws to attach signs to walls, creating a modern, three-dimensional effect. Standoff screws secure the signage while allowing it to project away from the surface, which increases visibility and impact.

The assembly process starts with attaching the sign to standoffs. Standoffs come in various styles, including male/female, male/male, and female/female configurations. Each type serves specific mounting requirements, ensuring flexibility for different signage solutions. For instance, edge-grip standoffs don't require holes in the sign, allowing for various design options.

When mounting the signs, we recommend using multiple screws for secure support. This ensures durability, particularly for heavier materials like acrylic or metal. Predrilled holes allow for straightforward installation, promoting optimal alignment. For best results, we encourage placing one screw at each corner and an additional screw in the center.

We appreciate how standoff screws aid in the balance of functionality and aesthetics. In particular, they allow for easy replacements of signage, maintaining a fresh look without extensive effort. Changing signs can be seamless, making it an ideal choice for environments requiring frequent updates, like restaurants or corporate offices.

This innovative approach sets our custom printing solutions apart. For maximum efficiency, we suggest exploring options like rigid signs and custom acrylic prints which leverage the advantages of standoff mounts.

Standoffs also contribute to structural integrity, ensuring that signage remains securely mounted. The floating effect from standoff signage not only elevates brand presence but also communicates professionalism and sophistication to clients and visitors. Whether opting for reflective surfaces or more traditional materials, the effect creates a lasting impression. Using reflective aluminum signs further enhances brand visibility, especially in low-light conditions, making your message clear and engaging.

By integrating standoff systems, we help businesses achieve an attractive, modern appearance for their signage, significantly raising brand visibility. For those looking to explore the oversized impact of signage, we recommend revisiting options within rigid sign printing.

Images of sample installations serve to illustrate how standoff signage operates within real-world settings, showcasing its effectiveness and versatility in enhancing brand presence. Integrating these elements into business signage transforms the visual narrative, combining style with practicality for any project.

Types of Standoff Screws for Signage

Standoff screws come in various types suited for different applications in signage. Understanding these types enhances our ability to choose the right solutions for specific needs.

- Male-Female Standoffs: These fasteners consist of a male end that screws into a wall and a female end that holds the sign. They offer stability and a clean look, making them popular for sign displays.

- Male-Male Standoffs: In this configuration, both ends are male, allowing for connection between two components. They are ideal for projects that require components to be attached together without a wall interface.

- Female-Female Standoffs: These feature threaded holes at both ends. They are less common but useful for connecting two pieces in a controlled environment, ensuring secure placement.

- Edge-Grip and Through-Grip Standoffs: Edge-grip standoffs attach to the sign's sides, avoiding the need for drilled holes through the signage. Through-grip standoffs pass entirely through the sign, providing a sturdy mounting solution for thicker materials.

Materials Used

Standoffs are available in various materials, including:

- Brass: Known for durability and attractive aesthetics, brass standoffs are common in high-end sign displays and enhance brand presence.

- Aluminum: Lightweight yet strong, aluminum provides resistance to corrosion and is ideal for both indoor and outdoor signage.

- Acrylic: Acrylic standoffs, often used in combination with acrylic prints, facilitate modern designs. They blend quality and style, perfect for contemporary visual presentations.

- Nylon: As a non-conductive option, nylon standoffs are valuable in electronic signage applications, ensuring safety while maintaining structural integrity.

Visual Appeal

The aesthetic qualities of standoff screws significantly contribute to the effectiveness of signage. The 3D effect created by standoffs enhances visibility and attracts attention. A well-configured standoff system emphasizes brand messaging and professionalism. At 4OVER4, we provide a range of printed solutions, including rigid signs that pair excellently with standoffs to create impactful displays.

Practical Applications

Standoff screws are essential in various industries, including retail and corporate environments. They support signage materials, such as glass, wood, and metal, catering to distinct design preferences.

The utilization of reflective aluminum signs in conjunction with standoffs offers enhanced visibility, particularly in low-light scenarios. This versatility allows businesses to present a professional appearance while conveying their message effectively.

Strength and Durability

Both functionality and durability are prominent features of standoff screws. For optimal support, we recommend using multiple screws, especially for larger or heavier signage.

Most projects require a minimum of 4 to 6 screws for secure installation, allowing for a reliable and long-lasting display. Additionally, materials like stainless steel offer increased resistance to wear and tear, ensuring longevity in both indoor and outdoor environments.

Ultimately, selecting the right type of standoff screw directly influences the effectiveness and durability of signage displays. By leveraging the customizable options at 4OVER4, businesses can enhance their brand presence and ensure their signage stands out.

Step-by-Step Installation Guide

We recognize the importance of a precise installation process for standoff screws in both electronic assemblies and signage solutions. Follow these steps for a successful installation.

- Gather Materials: Ensure all required tools and materials are available, including standoff screws, a screwdriver, and, if necessary, a spanner.

- Prepare the Surface: Clean the area where standoffs will be mounted. A clean surface guarantees optimal adhesion and alignment.

- Mark Drill Points: Use a pencil to mark the locations for drilling. Maintain a consistent spacing to ensure even placement of all standoffs.

- Drill Holes: Carefully drill holes at the marked points. Choose drill bits that match the size of the standoff screws.

- Insert Standoffs: Place the standoff screws into the drilled holes. For male/female configurations, ensure the threaded end aligns properly with the surface.

- Secure Standoffs: Tighten the standoffs using your screwdriver or spanner. Properly securing them enhances stability and maintains the necessary distance.

- Mount Components: Position the components, such as printed circuit boards or signs, onto the installed standoffs.

- Final Tightening: Ensure all connections are tight and secure. This step prevents any movement and maximizes the effectiveness of the standoff configuration.

Incorporating standoff screws increases the efficiency of electronics by allowing airflow and electrical insulation. For signage projects, standoffs elevate visual appeal while communicating professionalism and sophistication. Explore various materials, such as reflective aluminum for enhanced visibility, especially useful in low-light conditions. This feature not only attracts attention but also conveys brand messaging effectively.

We recommend looking into customized options available at 4OVER4 for superior printed solutions that enhance your brand's presence through rigid signs. With diverse design capabilities, 4OVER4 offers flexible options for businesses to achieve the perfect aesthetic and functional outcomes.

The performance and aesthetic qualities of various materials, including acrylic prints and coroplast, assist in promoting business brands effectively. Check out the advantages of using acrylic prints for signage that makes a lasting impression. Understanding the installation notice on ensuring strength and durability also contributes to maintaining an effective display over time. For further insights on material choices, explore rigid sign printing options to see which suits your needs best.

Best Surfaces for Standoff Signage

Standoff signage attaches securely to several surfaces, enhancing visibility and aesthetic appeal. The following surfaces work best for mounting standoff signs:

- Drywall: Excellent for interior applications, drywall provides a solid backing. Use wall screws for a stronghold.

- Masonry: Ideal for outdoor signage, masonry surfaces require appropriate anchors to ensure durability against weather elements.

- Metal: Standoff signs on metal surfaces deliver a sleek, modern look. Ensure proper drilling techniques for best results.

- Wood: Versatile for a variety of settings, wood requires pre-drilled holes for standoff screws to maintain integrity and alignment.

When planning to install signage, consider the weight and size of the sign. Heavy signs may need more screws, with an average recommendation of four to six screws for stability.

The reflective aluminum signs enhance visibility in low-light conditions, making them a popular choice for outdoor environments. For indoors, custom acrylic prints offer durability and clear graphics, elevating branding effectively.

4OVER4 provides tailored solutions for mounting standoff signage, offering design templates and high-quality materials that match our clients' specific needs. By creating visually striking signs, businesses can effectively convey their messages to customers.

Images of installations showcasing standoff signage mounted on drywall, masonry, and wood surfaces can illustrate the versatility of this mounting solution. Additionally, examples of reflective aluminum signs can highlight their effectiveness in practical settings, inspiring businesses to explore rigid sign printing options for enhancing brand presence.

By selecting the right surface and mounting method, standoff signage can significantly affect the perception of any space, making the choice of material and installation technique crucial for achieving desired outcomes. Leveraging our expertise, we assist businesses in elevating their brand presence with thoughtful, innovative signage solutions.

Benefits of Using Standoff Mounting

Standoff mounting offers significant advantages for both electronic assemblies and signage applications. It enhances airflow and provides electrical insulation, which is crucial for maintaining the longevity of electronic components.

- Improved Visibility: Standoffs create a visually appealing three-dimensional effect. This effect elevates signage, making it more striking and attention-grabbing. Displays using standoff screws stand out, contributing to brand presence and communication.

- Enhanced Durability: Standoff systems secure components firmly while preventing stress and damage that may occur due to inadequate mounts. With multiple screws used for heavier signs or structures, the stability increases, ensuring that installations remain intact.

- Material Variety: Standoffs come in various materials, such as brass, aluminum, and acrylic, accommodating different aesthetic needs and structural requirements. Each material lends distinct operational properties and durability values, enhancing functionality and brand image.

- Easy Maintenance: Standoff signage allows for quick and easy updates or replacements. This feature is particularly beneficial in dynamic environments where signage needs frequent changes.

- Professional Appearance: Standoff mounting communicates sophistication and credibility. This professional finish is vital for creating a positive first impression on clients and visitors.

By utilizing 4OVER4's custom printing solutions, businesses can effectively elevate their brand presence with engaging designs. From stunning rigid signs to captivating acrylic prints, 4OVER4 provides tailored options that maximize visual impact. Explore our offerings to enhance your signage capabilities with solid performance.

For further exploration, check out our offerings on rigid signs, reflective aluminum signs, and acrylic prints. These products not only enhance visibility but also reflect a business's commitment to quality and modern design principles.

Utilizing standoffs in installations communicates professionalism, while also providing functional benefits for spacing and airflow—making them suitable for a wide array of applications across various industries. With the right standoff mounting solutions, businesses can effectively manage component placements that positively impact workflows and audiences alike.

Design Tips for Standoff Signage

Designing effective standoff signage elevates brand presence and visibility. Here are essential tips to enhance your signage’s impact:

Choose the Right Materials

- Select durable materials like brass, aluminum, and acrylic to ensure longevity and a polished look. Each material adds unique aesthetic value, helping to communicate professionalism.

- Incorporate reflective materials to increase visibility, especially in low-light conditions. Utilizing reflective aluminum signs

enhances brand recognition at all times.

Optimize Size and Configuration

- Consider proportions that match the space. Large signs can attract attention, while smaller signs might fit better in more subtle settings.

- Select standoffs based on the sign's weight and mounting surface. Use through-grip standoffs for secure attachment, or edge-grip types for a clean look.

Focus on Installation Techniques

- Use multiple screws for sturdy support, particularly with larger or heavier signs. Placing screws at corners and center points reinforces structural integrity.

- Ensure proper pilot holes are drilled in advance to avoid damaging the sign during installation. Following these steps guarantees a secure mount.

Enhance Visual Appeal

- Create contrast between the sign and the background. A well-contrasted sign captures attention while remaining easy to read.

- Implement a three-dimensional effect using standoff kits that maintain a gap between the sign and the wall, producing a modern aesthetic. This effect visually separates the sign from the surface, making it more engaging.

Customize for Brand Identity

- Incorporate branding elements such as logos and taglines in the signage design. Tailor your visuals to align with your company's mission and values.

- Explore custom printing options at 4OVER4 to elevate the quality of signage materials, ensuring a cohesive look across your marketing strategies.

Consider Placement Impact

- Identify appropriate mounting surfaces such as metal, drywall, or wood. Each surface type might require specific screws and anchors for effective installation.

- Evaluate foot traffic flow in your space. Position signage in high-visibility areas to maximize impact and engagement with your audience.

By implementing these design tips, we can create effective standoff signage that enhances brand presence and captures attention effectively. To further enhance your visual communication, consider the various printing solutions available for customization through 4OVER4.

Conclusion

Standoff screws are vital for both electronic installations and signage solutions. They not only ensure proper spacing for airflow and safety but also elevate the aesthetic appeal of displays. By choosing the right type and material, we can achieve durability and visual impact that resonates with our audience.

Whether we're mounting PCBs or creating striking signage, standoff screws offer versatility and functionality. Their ability to enhance brand presence while maintaining structural integrity makes them an essential component in our projects. As we explore innovative applications and design strategies, standoff screws will continue to play a crucial role in our pursuit of excellence in both functionality and aesthetics.

Frequently Asked Questions

What are standoff screws used for?

Standoff screws create necessary gaps between electronic components to ensure proper airflow, prevent overheating, and avoid electrical shorts. They are crucial for mounting printed circuit boards (PCBs) and enhancing the functionality of various displays, including signage.

What materials are standoff screws made from?

Standoff screws can be made from various materials, including nylon, brass, aluminum, and stainless steel. Each material offers unique benefits such as durability, thermal conductivity, and aesthetic appeal, making them suitable for different applications in electronics and signage.

How do standoff screws improve airflow?

Standoff screws maintain a safe distance between components, creating space that facilitates airflow. This is particularly important in electronic assemblies, where enhanced airflow helps to dissipate heat and protect sensitive components from damage.

What types of standoff screws are available?

Standoff screws come in several styles, including cylindrical, square, and hexagonal designs. They also vary by gender, with configurations such as male-female, male-male, and female-female, each tailored for specific applications, such as PCB mounting or signage display.

How do you install standoff screws?

To install standoff screws, select the appropriate materials and ensure the surface is clean and stable. Use a drill to make holes for the screws, align the components, and secure them using multiple screws for added durability. Follow specific guidelines based on the application for optimal results.

What surfaces are best for mounting standoff signage?

Standoff signage can be effectively mounted on drywall, masonry, metal, and wood surfaces. It's important to consider the weight and size of the signs for stability and ensure the installation technique is suited to the chosen material for maximum impact.

Why choose standoff screws over traditional mounting methods?

Standoff screws provide better airflow and reduce the risk of damaging sensitive components compared to traditional mounting methods. They maintain a safe distance between parts, enhancing overall safety and performance, particularly in electronic applications.

Can standoff screws be customized?

Yes, standoff screws can be customized in terms of size, material, and design to meet specific application needs. Custom options allow businesses to enhance their brand presence and improve the visual appeal of signage or electronic setups while ensuring functionality.

More from Graphic Design

31661

In today’s fast-paced business world, a well-designed business card can be your secret weapon. It’s more than just a piece of paper; it’

Matthew Prince

Feb 3, 2023

5254143

If you had to choose between a plain colored or bold colored custom envelopes, which one would you choose? Color influences a person to open a

Emma Davis

Jul 18, 2020

5324147

Are you aware that

Emma Davis

Jun 17, 2020

3504751

So, you've decided to take the leap and print flyers

Emma Davis

Jun 4, 2020

3904387

One of the most perfect ways to showcase your company brand is by use of custom hang tags. These serve as a brilliant opportunity to have cust

Emma Davis

May 28, 2020

4824361

Marketing allows a vast window for business creativity in today’s world. One of those creative marketing gimmicks is the use of perforated w

Emma Davis

May 21, 2020

3453607

Have you ever received a postcard? If you have, you must know how warmth-inducing and thought-provoking they are. Now how would you feel if yo

Emma Davis

May 14, 2020

6063698

If you have been in any business; big or small, you know that it takes a lot of small efforts to make a big milestone. You also understand how

Emma Davis

May 14, 2020